For many vehicle owners, a garage is a special room that performs several functions at once. This is not only a convenient and safe parking lot for your car but also a suitable space for repairs and storage of boxes of household items, as well as a room for organizing get-togethers with your friends. That is why the floor covering should be as practical, reliable, and durable as possible.

SPECIFICITY AND FEATURE OF MATERIALS FOR ARRANGING GARAGE

Any impacts and loads associated with the operation of the garage affect the floor. Firstly, because a vehicle will regularly move along it. Secondly, during auto repairs, heavy tools and other accessories may fall down. Thirdly, there is always a high probability of spillage of fuel and lubricants and other technical fluids used when servicing the machine.

The floors in the garage must be equipped with materials that are resistant to any external influences. To do this, they must meet a number of requirements. It:

- high strength;

- resistance to regular heavy loads;

- fire safety;

- resistance to high humidity conditions;

- resistance to temperature extremes and spilled water freezing;

- resistance to aggressive substances (antifreeze, oils, cleaning agents, etc.);

- practicality;

- wear resistance.

An economy can also be added to this list. It is quite natural that every car owner wants to purchase materials with an optimal price-quality ratio.

WHAT ARE THE MOST COMMON OPTIONS?

Materials that are suitable for installing a garage floor have certain pros and cons. Accordingly, the flooring also acquires certain features, corresponding or not to the ideas of car owners.

CONCRETE in a garage – the traditional way

Concrete is the most common option and can be considered as an almost ideal solution when installing garage flooring. A concrete floor can be used as a finished base, or as a starting layer for further finishing.

The choice of garage owners in favor of this option is justified by the whole advantages of the material:

- resistance to heavy loads;

- high strength;

- the ability to create a flat and smooth surface;

- low price;

- the ability to pour concrete on your own;

- resistance to high humidity, temperature extremes, and aggressive chemical compounds;

- resistance to fire.

Those who want to quickly and economically make such flooring in their garage should pay attention to the fact that the finished floors will be very cold. Therefore, this option is suitable only for heated or used only for parking spaces.

In addition, concrete requires additional surface treatment. After the material is completely dry, its surface should be covered with a special compound. Otherwise, the concrete will begin to wear off, causing dust and dirt to appear under your feet. For finishing concrete floors in the garage, you can use special paint. The painted surface looks more attractive and lasts a very long time.

A quick option for a modern garage – SELF-LEVELING FLOORS

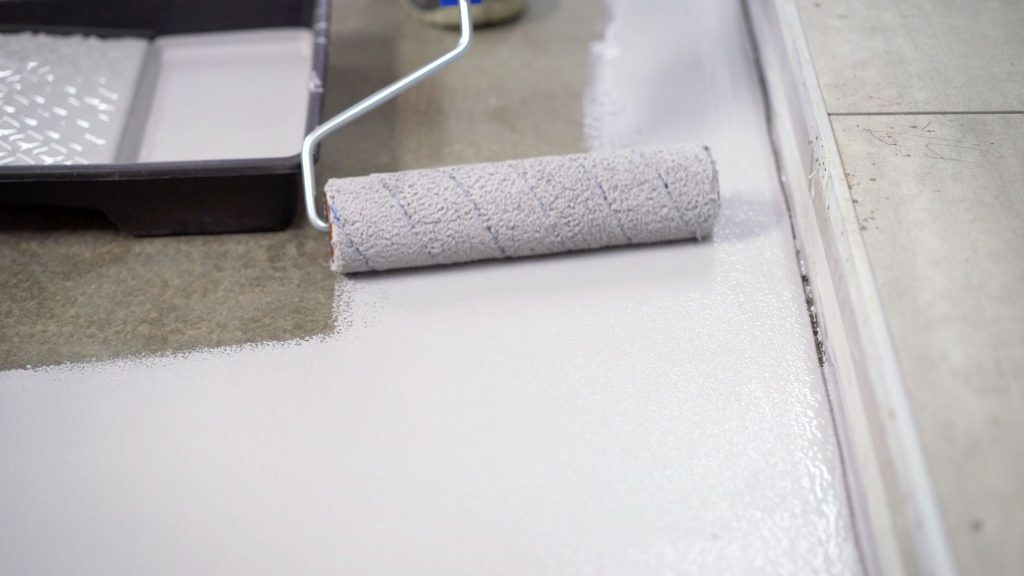

If you are interested in creating a perfectly flat, smooth, and durable surface underneath, look no further than self-leveling floors. Their use allows you to achieve the desired result in the shortest possible time. The mixtures used for arranging such floors differ in purpose, composition.

- Cement mixtures – they are intended for leveling the main surface. They do not have a decorative function, but they perfectly help to eliminate minor defects and irregularities. Their advantages are low cost and ease of use, moisture resistance.

- Polymer self-leveling floors – they are poured onto cement mixes, which, in turn, were used over the concrete screed. The advantages of this material: wear resistance, durability, resistance to temperature extremes and cold, resistance to moisture, fire, chemicals, hygiene, as well as ease of care and maintenance.

Polymer self-leveling floors are a practical and successful option for garage premises. They are subdivided into polyurethane, epoxy, methyl methacrylate, cement-acrylic. Such materials are expensive, but they but their technical characteristics are excellent.

Polymer self-leveling floors are a practical and successful option for garage premises. They are subdivided into polyurethane, epoxy, methyl methacrylate, cement-acrylic. Such materials are expensive, but they but their technical characteristics are excellent.

A popular material for finishing the floor in the garage – RUBBER

Rubber flooring is a coating that meets all technical requirements and meets the car owners’ ideas about reliable and durable garage floors. The basis of this material is crumb rubber. It is combined with plasticizers, various adhesives and dyes to form the ideal material for molding.

Rugs, tiles, and rolls can be made from the rubber compound, which can be used to quickly and conveniently cover the floor in the garage. Also, liquid rubber can be used for the arrangement of floors.

The advantages of rubber flooring are many:

- high anti-slip properties;

- durability and wear resistance;

- good thermal conductivity;

- soundproofing properties;

- resistance to mechanical stress and shock loads;

- resistance to temperature extremes;

- the ability to operate in high humidity conditions;

- high level of comfort due to the elasticity of the material;

- the simplicity of care and operation.

The main disadvantage of the floor of their rubber products is the possibility of fire. Therefore, such a floor should not be laid close to a fire source or additionally protected after installation.

Modern and non-standard solution – PAVING SLABS

The high technical characteristics of paving slabs fully allow its use for arranging the floor in the place where the car is planned to be parked. The use of tiles guarantees high durability and the aesthetic appearance of the floor covering.

The advantages of this finishing option can be considered:

- excellent durability – even under regular heavy loads, paving slabs will retain their basic qualities and attractive appearance for many years;

- wear resistance and durability;

- high fire safety;

- resistance to moisture and chemical compounds;

- ease of installation with the ability to lay the pattern;

- ease of maintenance.

It is worth purchasing paving slabs with a rough surface. It will be comfortable and safe to move along it. It is not recommended to buy strongly pronounced relief models because of difficulties with cleaning.

PORCELAIN STONEWARE is a great option for those on a budget

Porcelain stoneware is a good material for installing a garage floor. It is not inferior to natural stone in strength and is not cheap. Its advantages include:

- excellent durability (porcelain stoneware floors can last up to 50 years);

- unpretentious care and maintenance;

- high operational reliability;

- beautiful appearance;

- resistance to moisture, fire, temperature extremes.

However, this material has a small drawback – it has low thermal insulation qualities. It is recommended to lay porcelain stoneware on a concrete screed base.

A reasonable, but not very common option is the installation of ACID-RESISTANT TILES

Typically, the scope of application of special acid-resistant tiles is industrial workshops and manufacturing plants. Due to its excellent strength and resistance to aggressive acids, this material is also excellent for arranging garages.

Acid-resistant tiles are made of refractory clay with the addition of special substances to ensure the resistance of products to external factors. This material has the following advantages:

- high fire safety;

- high quality and durability;

- extreme resistance to acids and aggressive substances;

- resistance to temperature extremes, the ability to operate even at very low temperatures;

- simplicity in care and operation;

- excellent anti-slip characteristics;

- moisture resistance.

The disadvantages of acid-resistant tiles can be attributed only to the fact that the materials are made in a small range of colors. But given the scope of the products, this factor is unlikely to confuse garage owners.

STEEL FLOOR- the choice for quality and durability

The option of arranging the floor in the garage with steel panels is very attractive, but not common. This is due to the high cost of materials.

Advantages of corrugated steel plates:

- excellent wear resistance and durability;

- high strength;

- comfortable and easy to clean;

- good anti-slip qualities;

- resistance to heavy loads, including shock;

- the ability to install it on your own.

Generally, steel floor slabs in a garage are not difficult to install. The main difficulties are associated with the preparation and cutting.

In addition to the above options, there are two more – earthen floors and wood. The low cost of using such flooring for some users makes up for the lack of numerous advantages of the materials. However, these options are extremely rare, as most car owners strive to create a more reliable, stronger, safer, and more durable floor in their garage.